Introduction:

This article will introduce the filtration challenges of a paint manufacturing company and share their experience in choosing our stainless steel 304 450 screen machine. By using our customized screen machines, the company successfully solved the problem of paint filtration and improved filtration efficiency and product quality.

background:Paint Company, a well-known paint manufacturer, has been facing challenges in the filtration process. Due to the presence of particles and impurities in the paint, traditional filtration equipment cannot meet their needs. They needed an efficient and accurate filtration solution that could remove fine particles without compromising the quality and finish of the paint.

solution:

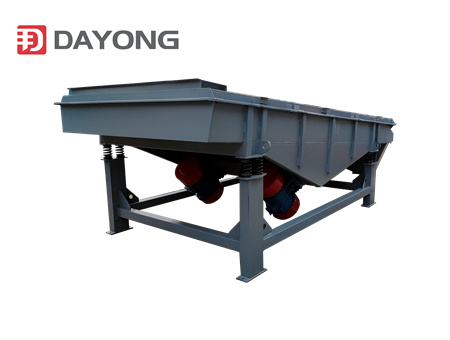

In communicating with Paint Company, we understood their needs and challenges and provided our stainless steel 304 450 screen machine as a solution. This screen machine is made of high-quality stainless steel 304 material, equipped with a mesh size of 325, and is suitable for filtering fine particles in paint.

Paint Company has experienced significant improvements after using our

stainless steel 304 450 screen machine. First of all, this screen machine can efficiently filter paint, remove particles and impurities in it, and ensure the quality of the product. Secondly, the production capacity of the screen machine has reached 1200kg/h, which meets their production needs and improves production efficiency.

In addition, our stainless steel 304 450 screen machine also has stable and reliable performance and is not easy to block and leak, reducing production line downtime and maintenance costs. The corrosion resistance and hygiene of stainless steel 304 material also ensure the purity of the parts in contact with the paint and the machine.

in conclusion:

By selecting our stainless steel 304 450 screen machine, Paint Company successfully solved its filtration challenges and increased the efficiency and quality of its paint production. Our customized solutions and high-quality screening machines bring them considerable profits and competitive advantages.

We welcome more paint manufacturers to cooperate with us and customize suitable filtration equipment according to their own needs to jointly promote the development of the industry.