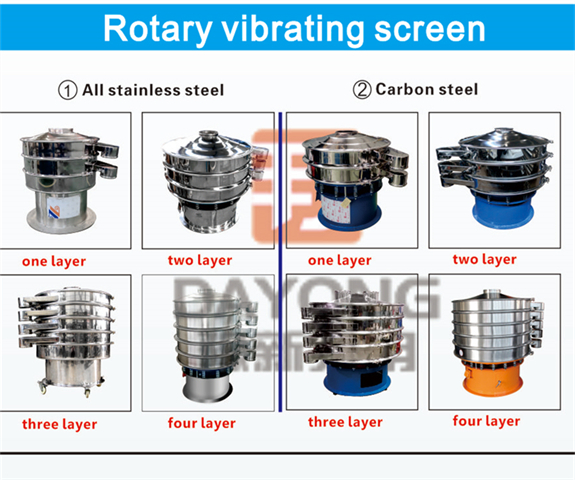

Features

1. Convenient replacement screen mesh, unique design structure, only take 3 to 5 minutes.

2. Allow to use various screen meshes (nylon , carbon steel, stainless steel).

3. The vibrating screen is designed. Exquisite and easy to assemble, a person can operate vibrating sifter / vibrating screen.

4. Compared with other relevant brands manufacturer, have than heavy to screen area and high handling capacity of benefit.

5. The supporting frame mesh can support the screen mesh, to keep the screen mesh longer life, and reduce the consumptive material use of net, silt, widely used in food, chemical, pharmaceutical and other industries.

.jpg)