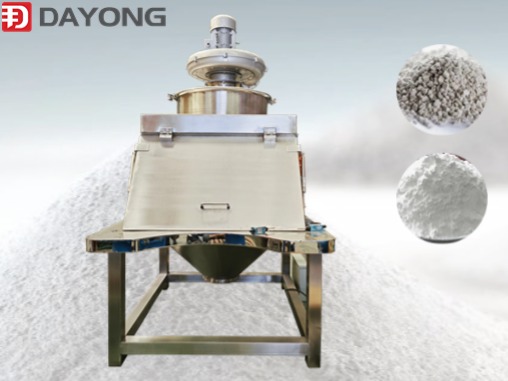

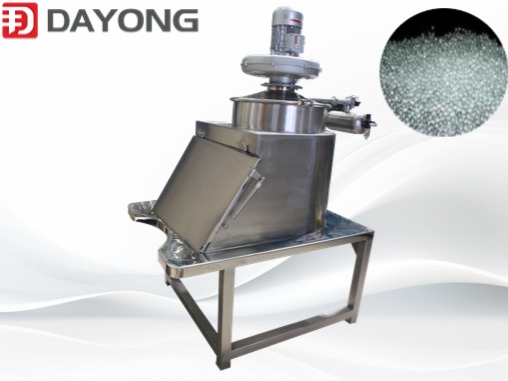

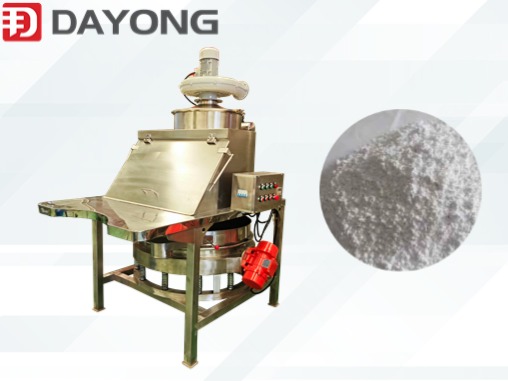

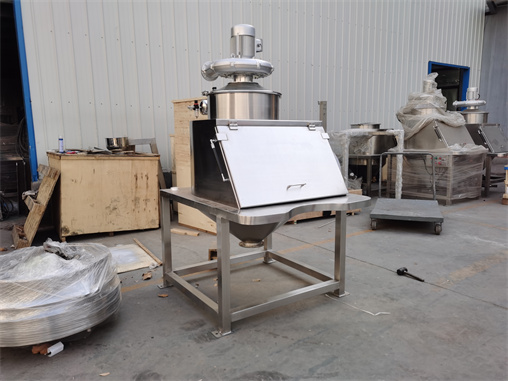

Low Noise Starch Powder Dust Free Dumping Hopper For Bulk Material

The dust-free feeding station mainly involves manually dismantling the belt and pouring materials into the equipment inside the dust-free feeding station. The negative pressure dust collection device is used to automatically extract the dust particles generated during the unloading process, avoiding the dust flying caused by traditional feeding methods

When the small bag material needs to be unpacked and poured into the next process, it only needs to be manually unpacked and put into the dust-free feeding station system. The material dust generated during feeding is collected by the dust collection fan. The material can be intercepted by a safety screen to block large pieces of material and foreign objects, thereby ensuring the discharge of particles that meet the requirements. The dust-free feeding station system is suitable for the feeding, screening, and unloading of small bags in industries such as new energy lithium-ion batteries, chemical, and food. It is particularly suitable for feeding and screening materials with poor fluidity. Due to the role of dust collection fans during unpacking, it can prevent material dust from flying everywhere. There are various production processes available for equipment, including single equipment for powder feeding and unloading, as well as important powder unloading in powder conveying systems such as single point multi feeding and multi point feeding.