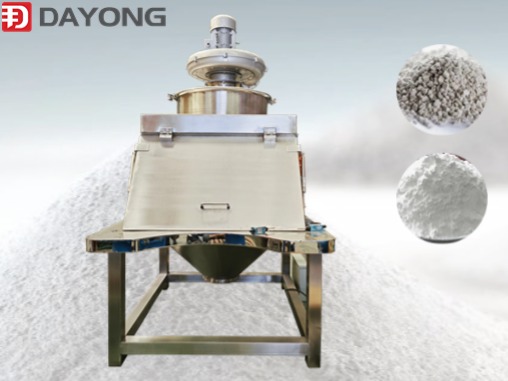

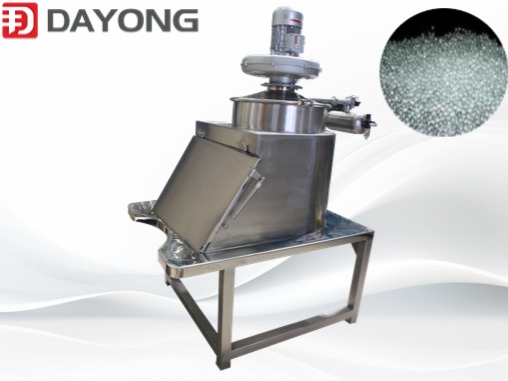

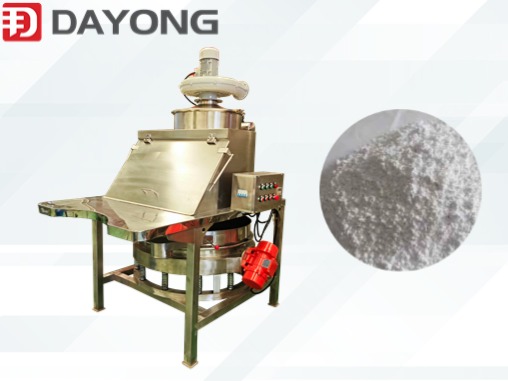

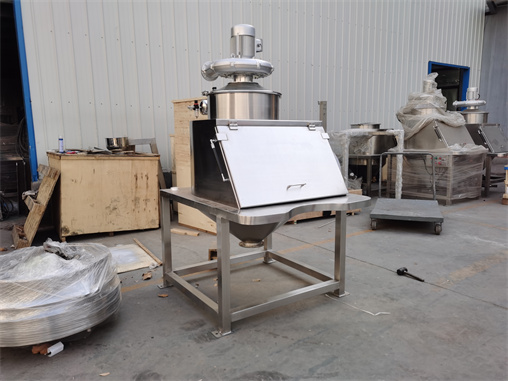

Dust free feeding station for chemical industry

When the bagged material is fed, there is a dust phenomenon. The dust-containing gas enters the platform box under the action of the induced draft fan at the feeding station, and the dust flows to the filter element with the airflow. The dust is trapped on the surface of the filter element and cannot be discharged with the gas, so as to achieve the effect of gas and dust separation. The whole process is sealed conveying, screening, no dust flying

The dust-free screening and feeding station is divided into upper and lower main parts, the upper part is for dust collection, and the lower part is for raw material screening or raw material transportation. The upper part collects the dust to the high-density filter element through the negative pressure fan. After a period of time, the filter element is blown back through the pulse device, and the dust falls into the lower straight screen for sieving. The principle of back blowing realizes the reuse of materials and ensures that the raw materials drain.

Lower screening equipment: It can be matched with inline screen, rotary vibrating screen, ultrasonic vibrating screen, screw conveyor and positive pressure or vacuum conveying system. The selection standard is determined according to the customer’s suitability for material screening and receiving.