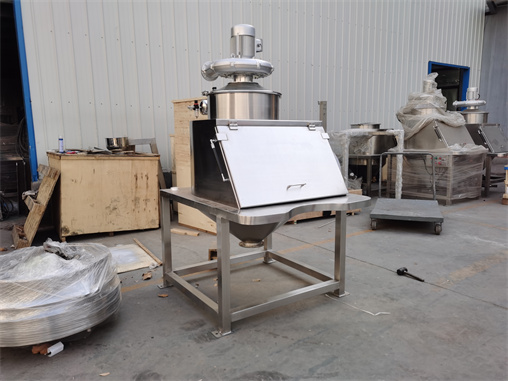

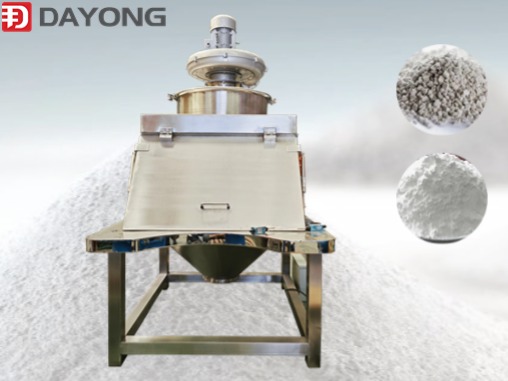

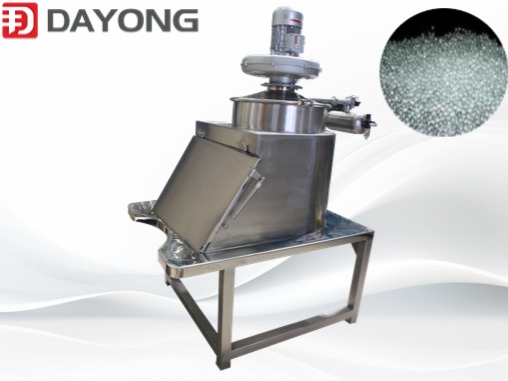

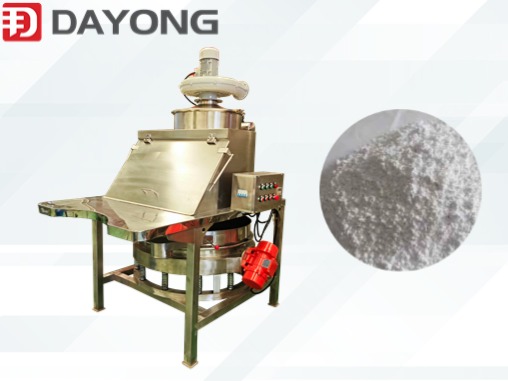

Bulk Material 25kg Flour Dust Free Hopper Dumping Hopper

The dust-free feeding station is suitable for unpacking, placing, screening, and unloading large, medium, and small bag materials in industries such as pharmaceuticals, chemicals, food, and battery materials. Due to the function of the dust collection fan during unpacking, it can prevent material dust from flying everywhere. When the material is unpacked and poured into the next process, it only needs to be manually unpacked and directly put into the system. The material passes through the vibrating screen, which can intercept large blocks of material and foreign objects, ensuring the discharge of particles that meet the requirements. It is composed of components such as a feeding platform, unloading silo, dust removal system, hopper/vibrating screen, etc.

The height design of the dust-free feeding station conforms to ergonomics, making it easy for workers to stand and work, reducing labor intensity. 4) The feeding efficiency is high. 5) The floor area is small, and it can be changed to a mobile or fixed position according to the actual situation. The above is a brief description of the dust-free feeding station by circular vibration machinery. If you have material feeding needs, please consult! What is a dust-free feeding station? A dust-free feeding station is a platform for manual feeding, suitable for feeding dry materials. It prevents dust splashing during the operation and is clean and hygienic throughout the entire process! The demand for environmental protection production is becoming increasingly high, and production enterprises can only abandon some traditional feeding methods and seek to eliminate the flying and splashing of dust in the production of powder materials

The bagged materials are manually placed on the feeding table, unpacked, and dumped into the dust-free feeding station silo. When the suction dust removal device works, the material dust is directly sucked into the dust collection device, and the material falls into the unloading silo before entering the next process. The characteristics of the dust-free feeding station: 1) comply with GMP production standards, and dust does not fly during work. 2) It can be flexibly connected to the next process (discharge silo can be connected to equipment such as screw conveyor, vacuum feeding machine, or direct mixing machine)! 3) The height design of the dust-free feeding table conforms to ergonomics, making it convenient for workers to stand and work, reducing labor intensity. 4) High feeding efficiency! 5) The floor area is small and can be changed to a mobile or fixed position according to the actual situation