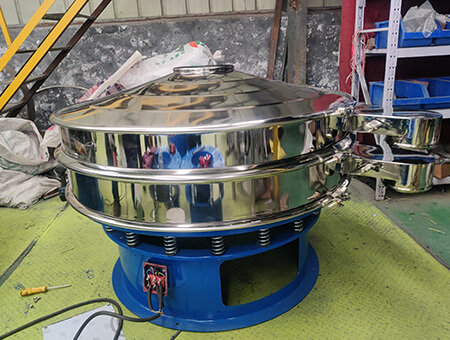

The material selection of the

ultrasonic vibrating screen also depends on the type of material being processed. For example, if the material is abrasive or has sharp edges, a stronger material such as stainless steel is required to withstand the wear. On the other hand, if the material is brittle, softer materials such as aluminum or copper alloys may be better suited to prevent damage to the product.

In addition, the shape and size of the material being processed also play a crucial role in determining the material used in the ultrasonic vibrating screen. Materials with irregular shapes or varying particle sizes may require a more flexible screen material, while smaller particles may require a finer mesh screen material.

In summary, selecting the best material for your ultrasonic vibrating screen is critical to ensuring optimum performance and longevity. Stainless steel is an excellent choice due to its durability, corrosion resistance and hygienic properties. It depends on the material being processed and the environment of use. Finally, the unique requirements of your application must be considered when selecting a material for your ultrasonic vibrating screen.