Tea is a traditional Chinese beverage with a variety of varieties and different processing techniques. High quality tea leaves are finely processed through over a hundred different techniques before being sold to the market. The quality of tea leaves also needs to be considered from multiple perspectives such as tea shape, aroma, and color. The purpose of tea linear screening is to ensure the optimization of "tea shape". Good tea leaves are plump and compact, with uniform thickness, intact and free from lumps and impurities. The function of a straight line sieve for tea leaves is to break down, remove impurities, and grade the tea leaves.

Tea chunking refers to the process of separating the unraveled tea leaves after they are kneaded and quickly lowering the temperature to avoid the occurrence of stuffy taste and insufficient drying, resulting in stuffy acidity.

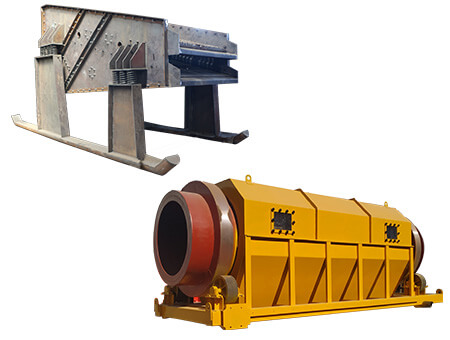

Pour the tea leaves that need to be screened onto the linear screen. Under the drive and excitation of the linear screen motor, the agglomerated tea leaves will be dispersed and evenly distributed on the screen surface. While achieving the purpose of deblocking, it can also complete the separation and removal of different sizes of tea leaves, broken tea, and impurities.

Tea linear screens can be made of two materials: carbon steel and stainless steel. Stainless steel linear screens are more hygienic, durable, and relatively expensive.

Characteristics of tea linear sieve:

1. The

linear sieve structure is simple and easy to operate, and one person can complete the processing of tea leaves;

2. The screening is smooth and gentle, without causing damage to the tea leaves;

3. The tea leaves have a variety of shapes and are equipped with net cleaning pinballs to promptly clean up clogged mesh holes without affecting the screening effect;

4. The tea linear screen can be designed with 1-6 layers of screen box screens, which can simultaneously remove impurities and grade 2-7 types of tea. It is usually recommended to use 2-3 layers (as shown in the video, the 2-layer screen screens out 3 sizes of tea);

5. The model is complete and the processing capacity is diverse. The conventional model can process 0.12-20 tons of tea per hour, and other needs can be customized.

Model of tea linear sieve:

The mesh size of the tea linear sieve can range from 0.038mm to 12.5mm. When its mesh size is greater than 0.08mm, the screening effect is the best. (The size of tea leaves is greater than 0.08mm)