Introduction:

Soybean powder is a commonly used ingredient in various food products, including baked goods, protein bars, and infant formula. To ensure the quality and consistency of soybean powder, it is important to grade the powder into different particle sizes. In this case study, we will examine how a 1000mm rotary vibrating screen was used to grade soybean powder.

Machine and Specifications:

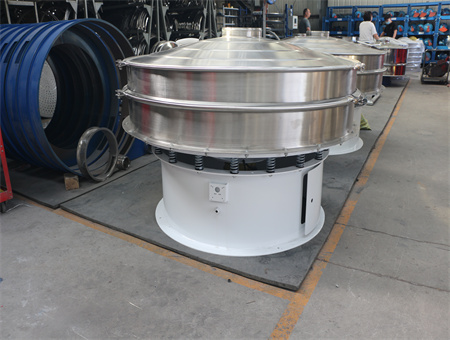

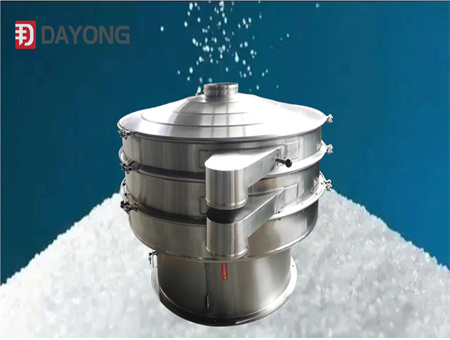

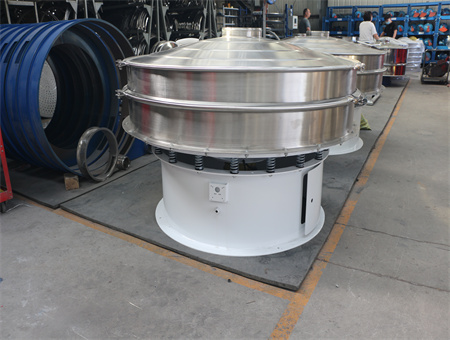

The machine used in this case study was a 1000mm rotary vibrating screen, which had three layers and three different screen mesh sizes: 40 mesh, 60 mesh, and 80 mesh. The purpose of the machine was to grade soybean powder into different particle sizes, ranging from coarse to fine. The machine was capable of processing up to 300kg/h of soybean powder.

Process:

The soybean powder was fed into the rotary vibrating screen through a hopper. As the machine was turned on, the powder was distributed across the three layers of the screen. The different screen mesh sizes were designed to capture particles of different sizes, allowing the soybean powder to be separated into different grades. The coarse particles were captured by the 40 mesh screen, while the medium and fine particles were captured by the 60 mesh and 80 mesh screens, respectively.

Results:

The

1000mm rotary vibrating screen was able to effectively grade the soybean powder into three different grades. The machine was able to process up to 300kg/h of soybean powder, which met the production requirements of the manufacturer. The different screen mesh sizes were able to capture particles of different sizes, resulting in a more accurate grading of the soybean powder.

Conclusion:

In conclusion, the 1000mm rotary vibrating screen was an effective machine for grading soybean powder. The machine's ability to process a large amount of material, along with its three layers and three different screen mesh sizes, allowed the soybean powder to be graded accurately and efficiently. By using this machine, the manufacturer was able to ensure the quality and consistency of their soybean powder, leading to better quality products and more satisfied customers.