Ultrasonic Vibration Filter Separator For Polishing Powder

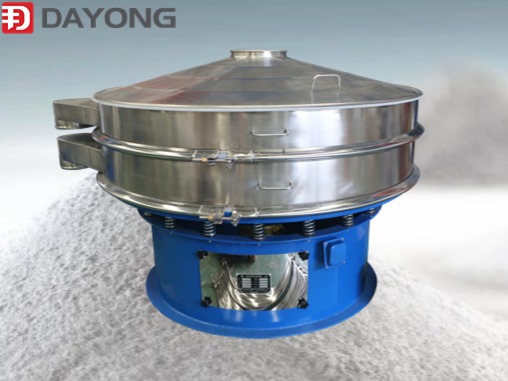

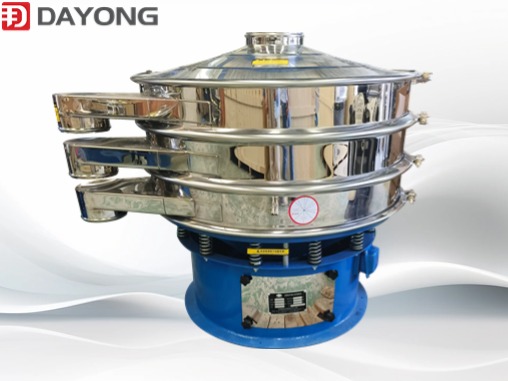

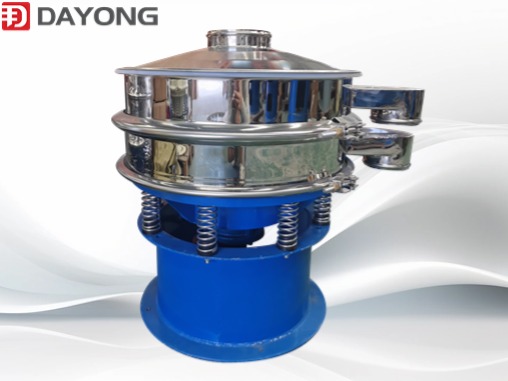

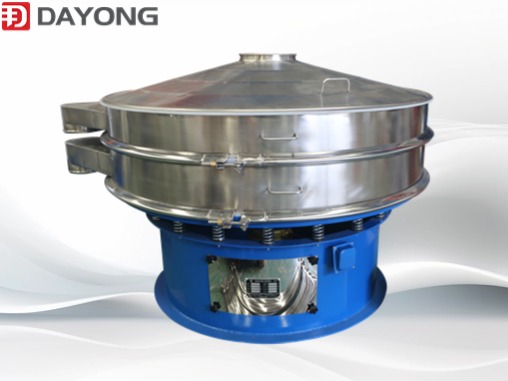

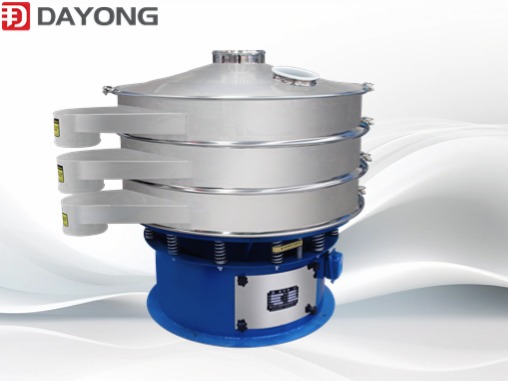

DY series rotary vibrating screen uses vertical motor as the excitation source, and eccentric hammers are installed on both sides of the motor, which can convert the motion into horizontal, vertical and inclined three-dimensional motion, and then transfer these three-dimensional motion to the materials on the screen surface. Adjust the phase angle of the upper and lower sides to change the movement track of the material on the screen surface. The rotary vibrating screen has high screening accuracy, convenient and fast operation.

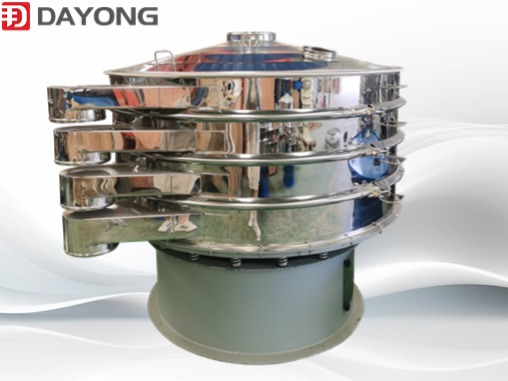

The round vibration screen is an inertial vibration screen of a single -axis circular weekly movement. The work of the round vibration screen depends on the inertia generated by the inertia motor and the eccentric board. Due to the vibration of the sieve box, the material is thrown out, so that a certain size of the material is sieved through the screen. Realize the screening goal. Because the magnetic motorizer is installed on the center of gravity of the sieve box, the two ellipse long shaft forms a Chinese character shape. The upper part of the elliptical long shaft of the import end is consistent with the exit direction, which is conducive to the diffusion of the material in the sieve box.

When the round vibration sieve runs, the material is first sent to the screen, and the material is evenly separated on the sieve mesh. The rolling bearings of the screen will be stressful by highly impact loads. Moreover, while rotating the sieve bearing around its own axis, it follows a method of circular, ellipse or straight vibration. This can lead to a high radial acceleration, thereby a large stress on the bearing, especially the maintenance of the shelf. Running speed is usually very high. Therefore, the bearing temperature is as high as 20 to 30 degrees. The Kailin is higher than the normal application. In addition, the severe deviation between the bearing position and the severe deflection of the shaft must be considered