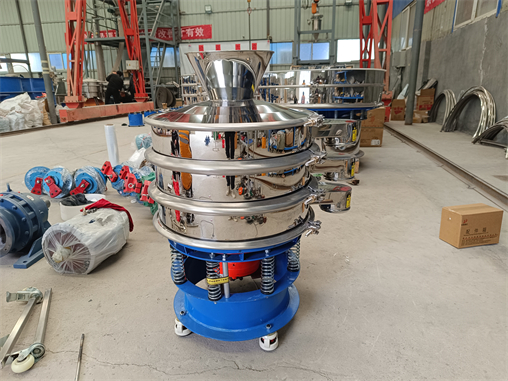

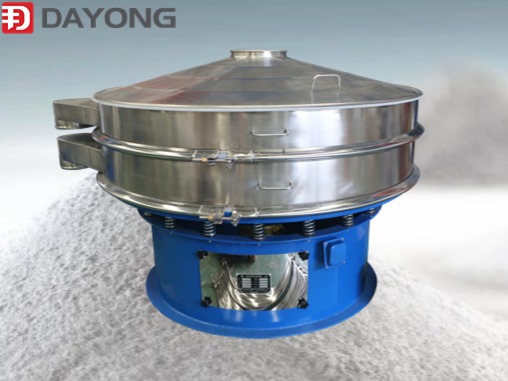

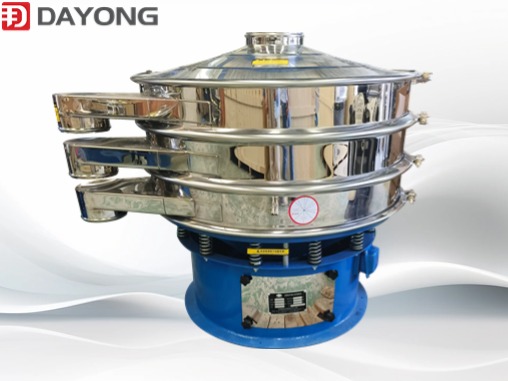

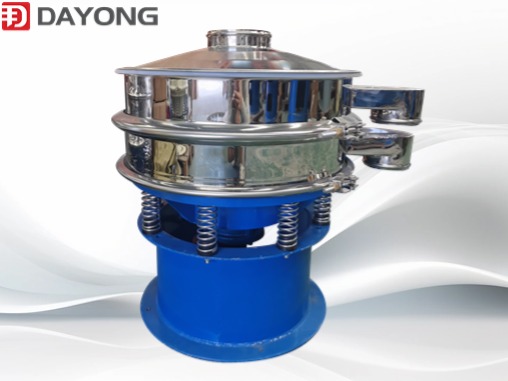

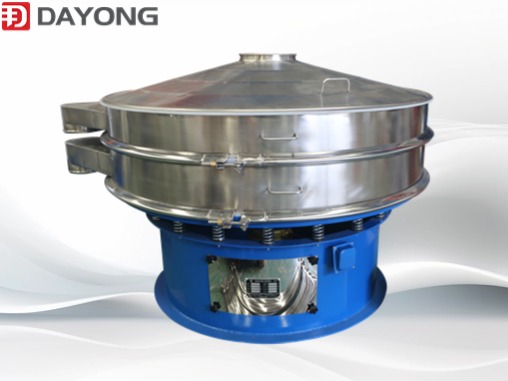

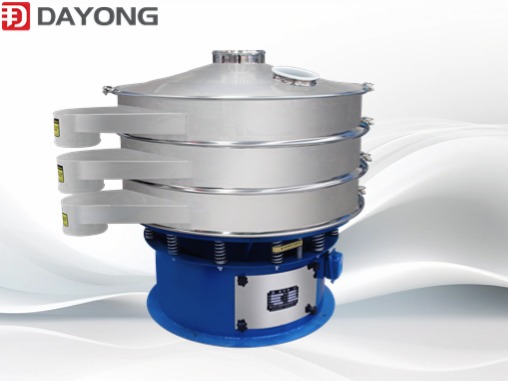

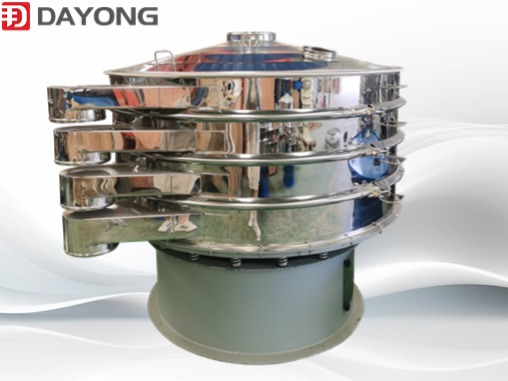

Stainless Steel Round Vibrating Screen For Seaweed Powder

The round vibration screen is an inertial vibration screen of a single -axis circular weekly movement. The work of the round vibration screen depends on the inertia generated by the inertia motor and the eccentric board. Due to the vibration of the sieve box, the material is thrown out, so that a certain size of the material is sieved through the screen. Realize the screening goal. Because the magnetic motorizer is installed on the center of gravity of the sieve box, the two ellipse long shaft forms a Chinese character shape. The upper part of the elliptical long shaft of the import end is consistent with the exit direction, which is conducive to the diffusion of the material in the sieve box.

Dayong Company is a manufacturer specializing in the design, development, manufacture of screening, conveying and other mechanical equipment. It has a mature technical research and development team, focusing on providing customers with professional customized products and differentiated services according to their actual needs.

The circular vibrating screen has high screening accuracy and high working efficiency, and is suitable for any particles, powders and slurries.

The circular vibrating screen is an inertial vibrating screen with a single-axis circular motion. The work of the circular vibrating screen depends on the inertial force generated by the inertial motor and the eccentric plate. Due to the vibration of the screen box, the material is thrown out, and the material of a certain size passes through the screen. The screening objective was achieved. Since the magnetic exciter is installed on the center of gravity of the screen box, the two long axes of the ellipse form the shape of Chinese characters, and the upper part of the long axis of the ellipse at the inlet end is consistent with the direction of the outlet, which is conducive to the diffusion of materials in the screen box.