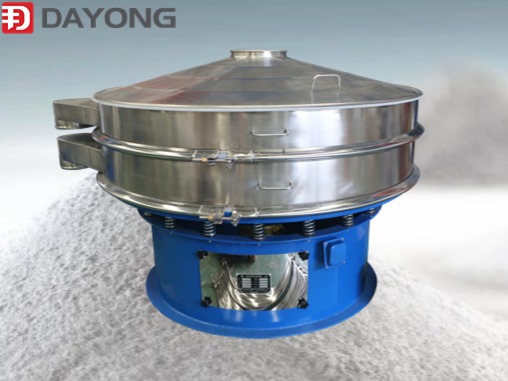

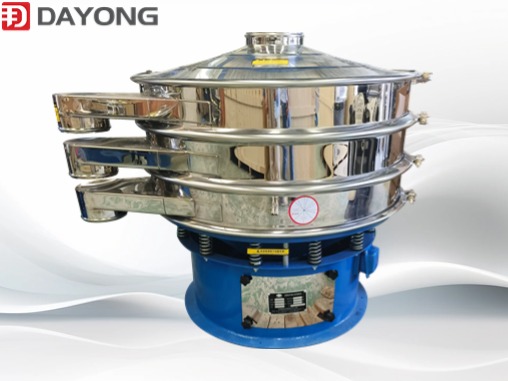

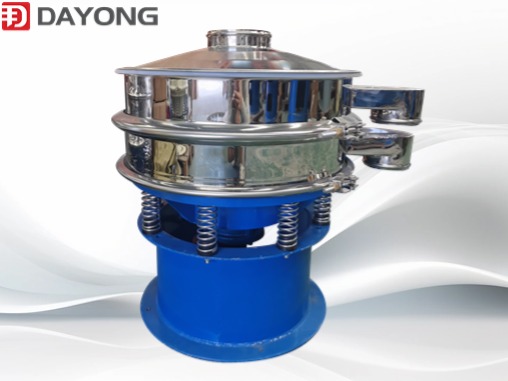

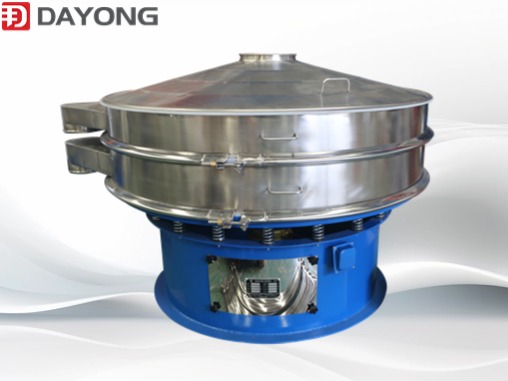

Mini Rotary Shaker Circular Vibration Screener For Flour Powder/vibration powder sieve/vibratory screening separator/vibro saparater

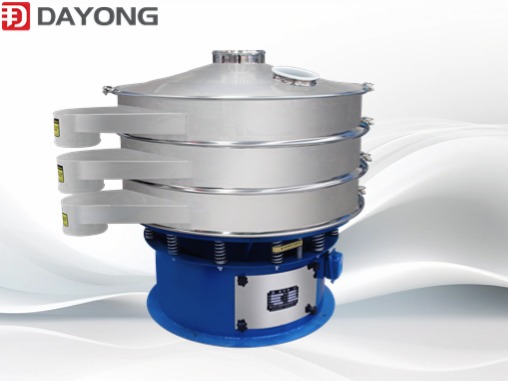

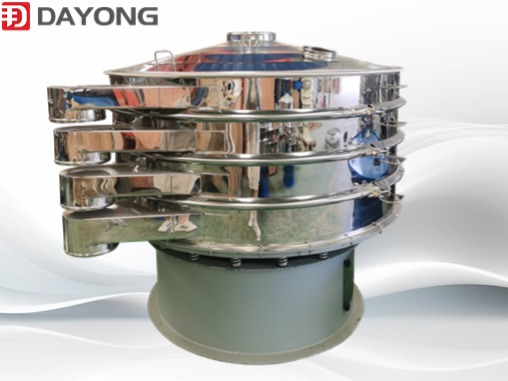

The Mini Rotary Shaker Circular Vibration Screener For Flour Powder, also known as a vibration powder sieve, vibratory screening separator, or vibro separator, is expertly produced and sold by Xinxiang Dayong Vibrating Equipment Co., Ltd. This device is specifically engineered for the precise screening of flour. Equipped with an automatic cleaning device, such as a bouncing ball mechanism, it ensures the mesh remains unobstructed, thereby enhancing screening efficiency. The screen mesh, reasonably tensioned and crafted from 304 stainless steel, boasts a long service life. Its innovative structure allows for quick and effortless installation and replacement of the mesh, taking just 3-5 minutes.

The Mini Rotary Shaker Circular Vibration Screener For Flour Powder, also known as a vibration powder sieve, vibratory screening separator, or vibro separator, is expertly produced and sold by Xinxiang Dayong Vibrating Equipment Co., Ltd. This device is specifically engineered for the precise screening of flour. Equipped with an automatic cleaning device, such as a bouncing ball mechanism, it ensures the mesh remains unobstructed, thereby enhancing screening efficiency. The screen mesh, reasonably tensioned and crafted from 304 stainless steel, boasts a long service life. Its innovative structure allows for quick and effortless installation and replacement of the mesh, taking just 3-5 minutes.

This advanced screener from Xinxiang Dayong Vibrating Equipment Co., Ltd. offers the flexibility to control the material’s movement trajectory on the screen by adjusting the angle of the two eccentric blocks. It utilizes a vertical motor as its vibration source, with eccentric hammers positioned on both sides of the motor. By modifying the phase angle of the upper and lower sides, the material’s movement path on the screen surface can be altered, enabling vertical, horizontal, and tilt movements of the machine. Additionally, it can be equipped with a mesh – cleaning device to effectively prevent clogging. This vibrating screen is primarily utilized for screening, impurity removal, and filtration of powders, particles, and liquids, with screening capabilities as fine as 500 mesh (0.028mm) and filtration reaching up to 5 microns. It supports up to 4 screen layers, offers a comprehensive range of models, and can even be customized to meet specific requirements.