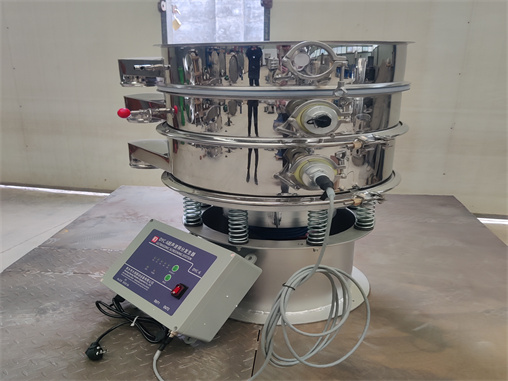

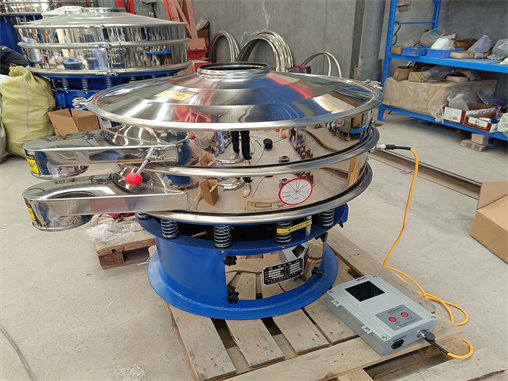

Ultrasonic Vibrating Screen For Battery Powder

Ultrasonic Vibrating Screen For Battery Powder is specially designed to solve the problem of Battery Powder sieving, single-layer use sieving to remove impurities, multi-layer use size classification, fine filtration. Equipped with an ultrasonic system to solve the phenomenon of static electricity and agglomeration of materials. Xinxiang Dayong Vibration Equipment Co., Ltd. has been specializing in the production of screening machines for 11 years. According to your specific needs, we can customize screening machines for you.

Machine model: DY-400mm/DY-600mm/DY-800mm/DY-1000mm/DY-1200mm/DY-1500mm/DY-1800mm

Machine material: stainless steel for parts in contact with materials; all stainless steel; carbon steel; plastic material.

Number of layers used: 1~5 layers

Welcome to contact us.

The screen machine is produced by China Xinxiang Dayong Vibration Equipment Co., Ltd. It is a high-efficiency vibrating screen machine developed for the screening of powder particles. It is widely used in food, medicine, chemical industry, metallurgy, abrasives, plastics, ceramics, glass, etc. Coatings, pollution treatment and other industries, effectively improve work efficiency and save production costs for customers.

The basic rotary motion is similar to manual screening, the eccentricity is adjustable from 25 to 40mm, The residence time of each product can be adjusted towards the drive axis by the radial and cutting angles of the rocking screen. Therefore, a three-dimensional tumbling motion for leveling and throwing is established. Carborundum is uniformly dispersed on the entire screen surface from the center to the outer edge, thereby propagating axially in a spiral motion. The fine particles thus complete the entire screening process. The horizontal and vertical accelerations increase with the movement of the particles, and the silicon carbide close to the mesh size is successfully separated; the larger particles are transported to the outlet, and the flow is controlled by an adjustable guide device, which is a Another factor that controls the residence time of emery. This process is repeated between each screen layer.