Ultrasonic Vibrating Screen For Cmc Powder

Carboxymethyl cellulose (CMC for short) is a commonly used food additive. Due to its special properties, there are many special requirements in the production and processing process, especially in the selection of screening machines. How to choose a screening machine?

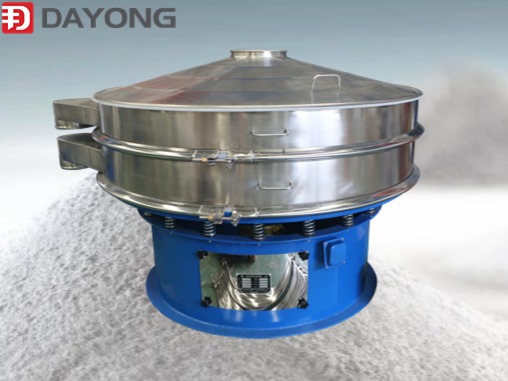

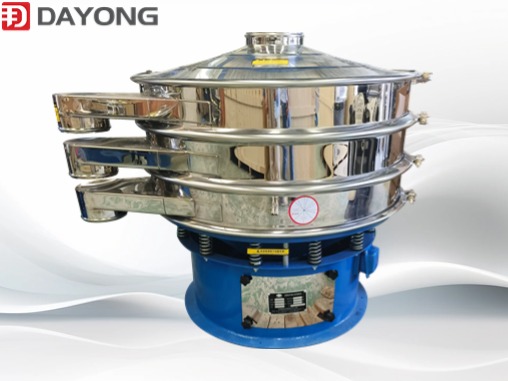

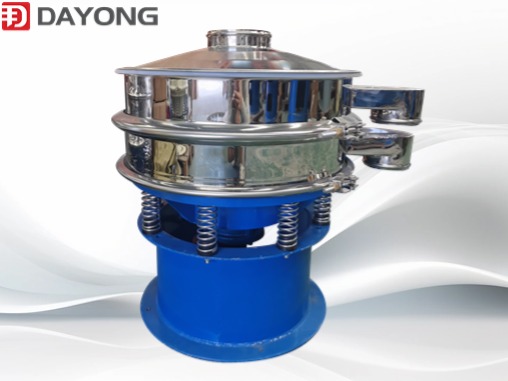

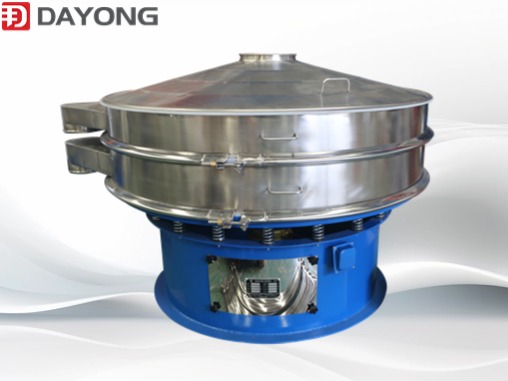

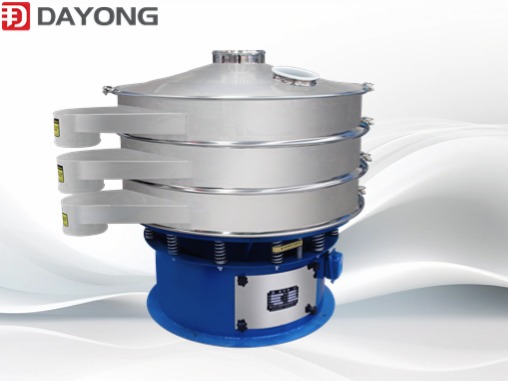

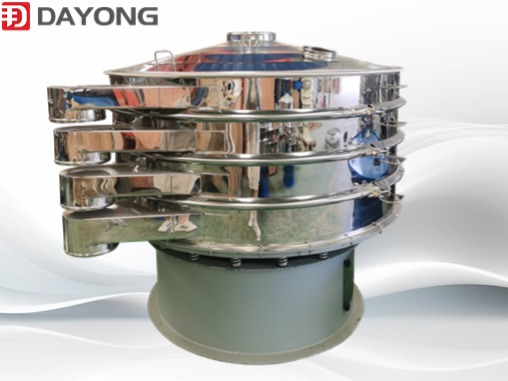

Dayong Company has professionally developed DY-400/DY-600/DY-800 and other different types of screening machines. According to the particle size of the material, choose different screen mesh specifications and screen grades. It can meet the special needs of some industries.

Carboxymethyl cellulose (CMC for short) is a commonly used food additive, and its sodium salt (sodium carboxymethyl cellulose) is often used as a thickener and paste. It is widely used in industrial production and brings huge use value to various production fields. Carboxymethyl cellulose is a powdery substance, non-toxic, but has a certain solubility. Due to its special properties, there are many special requirements in the production and processing process, especially in the selection of screening machines. How to choose a screening machine?

Dayong Equipment Co., Ltd., which specializes in the production of ultrasonic screening machines, provides important points for CMC to select screening machines. According to its own material content and screening purposes, it can choose suitable screening machines. The professional information provided by Dayong Vibration Equipment Co., Ltd. explains, First of all, it is necessary to clarify the structure and composition of the raw materials to be processed. According to the purpose of sieving, it is necessary to remove impurities, classify, filter or select the accuracy of sieving. Secondly, the size of the machine model is determined according to the processing capacity. For different processing capacity, Dayong Company has professionally developed different types of screening machines such as DY-400/DY-600/DY-800. The third is to choose the size of the mesh, and choose different mesh specifications and sieve grades according to the particle size of the material. Fourth, whether it can meet the special customization needs of some industries.