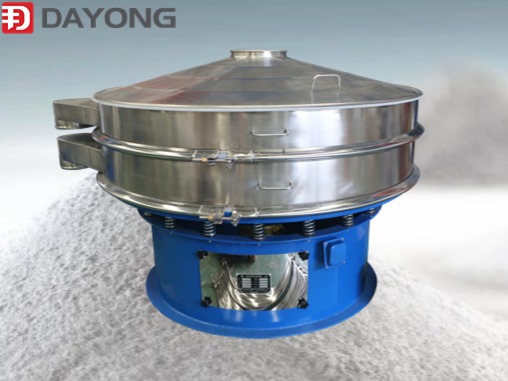

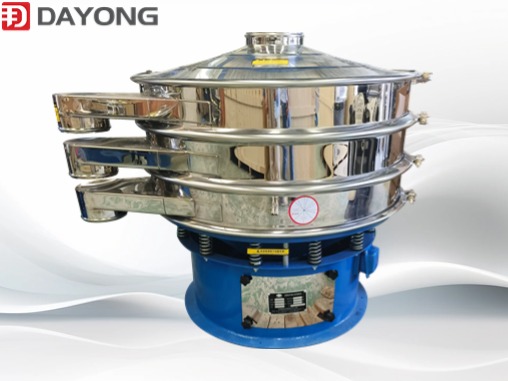

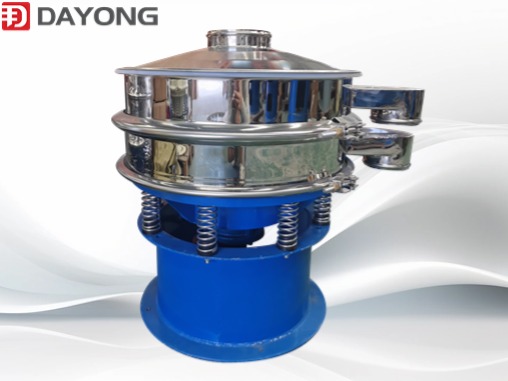

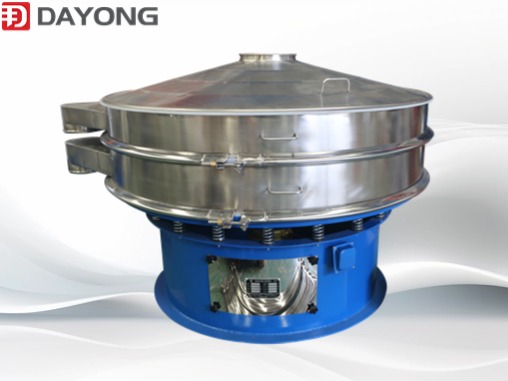

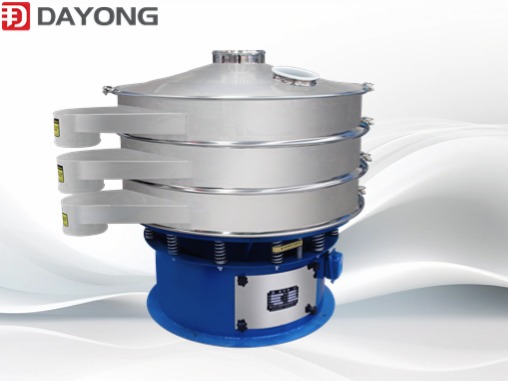

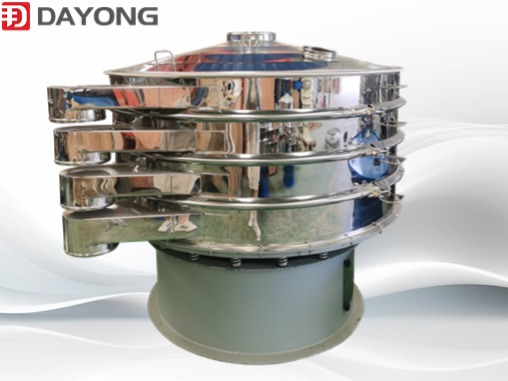

Ultrasonic Vibro Sieve/Rotary vibrating Screen

Why choose ultrasonic vibrating screen?

1. The ultrasonic vibrating screen screening equipment adopts PID control algorithm, which is fast and accurate, so that it always works at the frequency and current, which greatly improves the production capacity;

2. Decompose the adhering substances, reduce the objects on the screen, and the screen rate of the ordinary vibrating screen is increased by 5-20 times;

3. Accelerate the separation of agglomerates, high-precision, high-density, high-class, light specific gravity and adsorption materials, and speed up the screening throughput;

4. Unique screening system, no need to add any other screen cleaning device, it has self-cleaning function, the mesh is not blocked, etc.

Dayong Vibration Equipment Co., Ltd. specializes in the production of ultrasonic vibrating screens, and has provided customized services for many manufacturers in different industries at home and abroad, and has received unanimous praise. If you have any questions about the product and want to consult, please contact us, we will give You provide the best service.

Why choose ultrasonic vibrating screen?

1. The ultrasonic vibrating screen screening equipment adopts PID control algorithm, which is fast and accurate, so that it always works at frequency and current, which greatly improves the production capacity;

2. Decompose the adhering substances, reduce the objects on the sieve, and increase the sieving rate of the ordinary vibrating screen by 5-20 times;

3. Accelerate the separation of agglomerates, high-precision, high-density, high-class, light specific gravity and adsorption materials, and speed up the screening throughput;

4. The unique screening system does not need to add any other screen cleaning device, and it has the characteristics of self-cleaning function, and the mesh is not blocked;

5. The screening particle size is increased by 1%-100%, and the output is increased by 1-15 times, which can meet the screening treatment of fine particles above 400 mesh;

6. Fine particles with adjacent diameters can be clearly separated;

7. Does not change the characteristics of screening materials, especially for new materials;

8. Prevent the clogging of 50-625 mesh meshes and the clogging of meshes caused by similar particles, and prolong its service life;

9. The performance of the ultrasonic vibrating screen system will not make the operating temperature higher and work continuously, and the temperature rise can be controlled for drugs, thermosetting coatings and raw material operations;

10. It is suitable for 20 micron to 300 micron screen to separate powder, and has a good screening effect for some difficult-to-screen materials.

Dayong Vibration Equipment Co., Ltd. specializes in the production of ultrasonic vibro screener, and has provided customized services for many manufacturers in different industries at home and abroad, and has received unanimous praise. If you have any questions about the product and want to consult, please contact us, we will give You provide the best service.