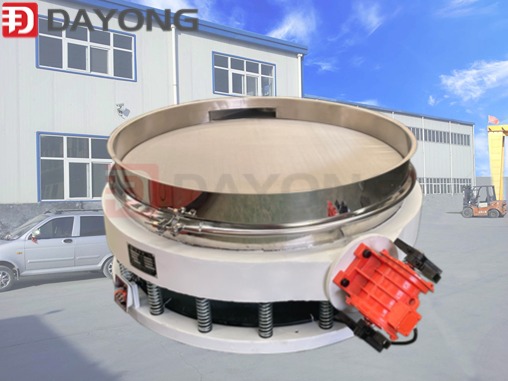

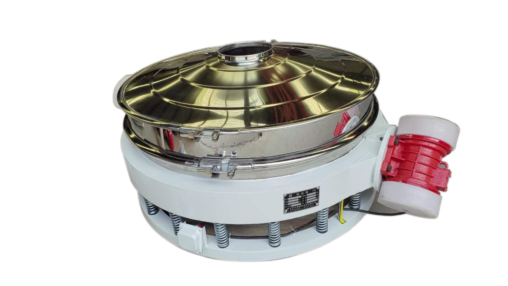

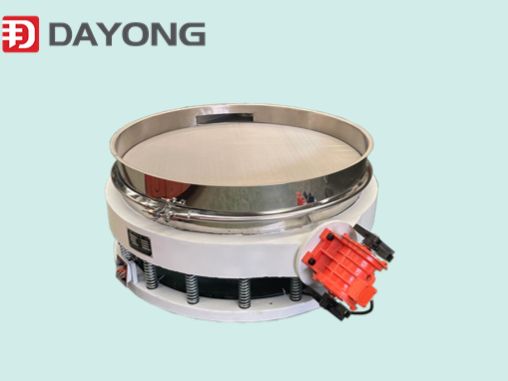

High Efficiency Bottom Output Wheat Flour Vibrating Sifter Equipment With Two Motors

The double motor high-efficiency bottom out wheat flour vibrating screen equipment produced and sold by Xinxiang Dayong Vibrating Equipment Co., Ltd. is specially used for the screening of wheat flour in the food industry.No assistant objects bring pollution to the powder body e.g. rubber ball. Increasing the through rate of 50%-400%.Structure completely constructed by stainless steel, grace appearance and longevity of operation.

Through the motor vibration to produce excitation force, by adjusting the motor at both ends of the eccentric hammer weight and phase angle can change the size of the exciting force, effectively change the material trajectory, to extend the material on the screen surface to stay.This type of direct discharging screen is new-type and multi-purpose. Different from the traditional one with dual-motor structure, this type of screen is with single horizontal vibrating electric motor. So the track of the material can be adjusted in multiple ways, and the equipment can become extraordinarily adaptable. Moreover, the material can be discharged directly, so the handing capacity is greater. This type of equipment is for rough screen and accurate screen of flour, starch, washing-powder, metal powder, additive, and other kinds of particle or powder in chemical, coal, and other related industry. https://www.dyvibratingscreen.com/products/vibrating-screen/direct-dishcarge-sifter.htmlWith great handing capacity, this type of equipment is easy to be applied to manufacture. Especially the DY-1000 screen, which has 24 meshes, performs outstandingly in the producing of instant noodles. In the screening, cleaning and loosing of wheat flour, its rate can reach 350 kg/150 s, and you have more options from 600 mm to 2000 mm.