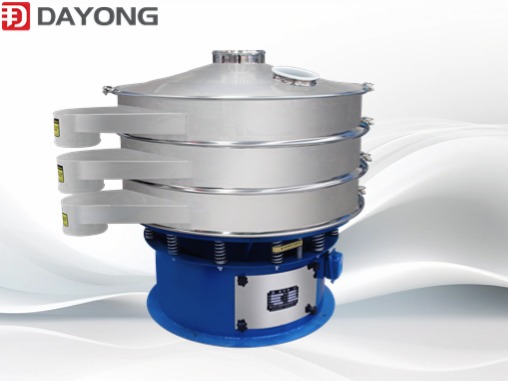

Efficient Material Classification for Tire Rubber Particles with Customized Rotary Vibrating Screens

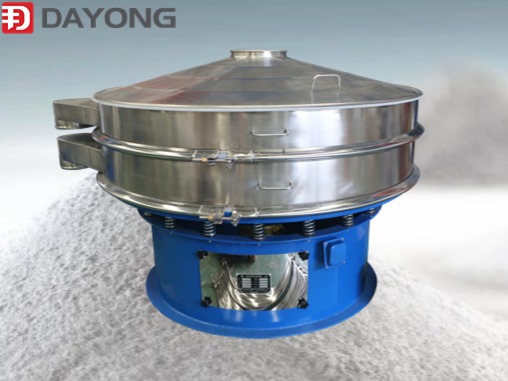

Welcome to our production factory, where we specialize in providing customized machinery solutions. We are delighted to introduce our advanced rotary vibrating screen, specifically designed for the classification of tire rubber particles. With a focus on efficiency, precision, and customization, our machines are engineered to enhance your tire rubber particle processing and improve the quality of your end product.

Welcome to our production factory, where we specialize in providing customized machinery solutions. We are delighted to introduce our advanced rotary vibrating screen, specifically designed for the classification of tire rubber particles. With a focus on efficiency, precision, and customization, our machines are engineered to enhance your tire rubber particle processing and improve the quality of your end product.

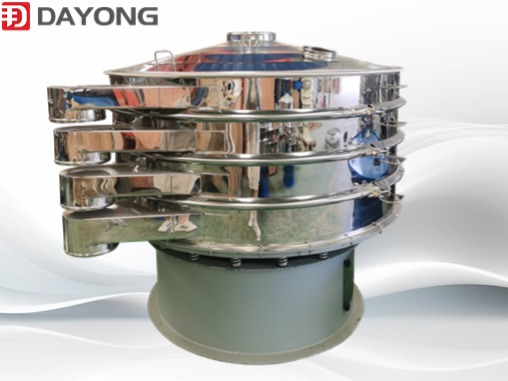

High-Quality Construction and Hygiene:

Our rotary vibrating screens are constructed using premium-grade stainless steel for the contact parts, ensuring compliance with strict hygiene standards. This material choice guarantees durability, corrosion resistance, and eliminates the risk of contamination, making it ideal for materials such as tire rubber particles.

Efficient Material Classification:

Equipped with a single sieve layer, our rotary vibrating screen is designed to efficiently classify tire rubber particles. The machine model 1500mm offers ample screening capacity to handle large quantities of rubber particles. The 6 mesh size ensures effective separation, allowing you to obtain tire rubber particles of desired sizes for various applications, such as recycling or further processing.

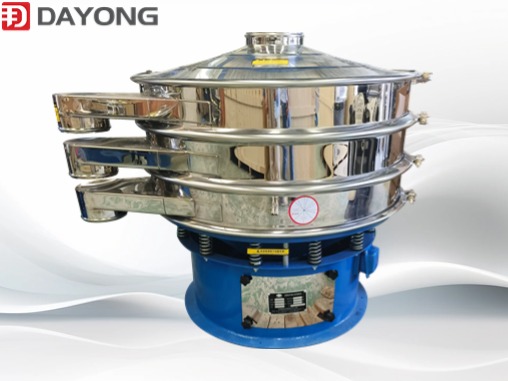

Customization for Enhanced Performance:

Understanding the unique requirements of each production facility, we offer tailored solutions to meet your specific needs. Our team of experts will collaborate closely with you to understand your production process and customize the rotary vibrating screen accordingly. Whether it’s adjusting the mesh size, optimizing throughput, or accommodating specific particle size ranges, we ensure that the machine perfectly aligns with your production goals.

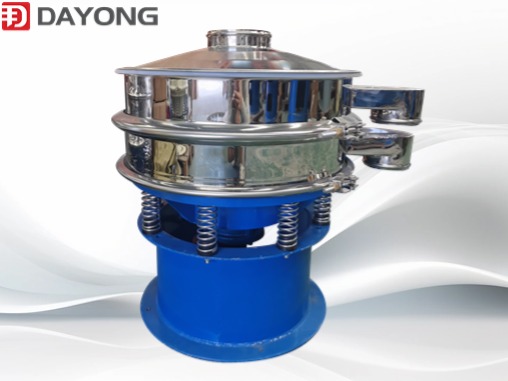

Reliable Performance and Accuracy:

The machine model 1500mm is designed for optimal performance and accuracy in classifying tire rubber particles. The rotary vibrating motion efficiently separates and classifies the particles, ensuring uniformity and consistency in the classification process. With precise control over the mesh size, you can achieve the desired particle size distribution for your tire rubber particles, enhancing the quality and usability of the end product.

Seamless Collaboration:

As a production factory, we prioritize customer satisfaction and long-term partnerships. By choosing our rotary vibrating screen, you gain access to advanced technology, customizable solutions, and exceptional customer support. Our experienced team will guide you through every step of the process, from initial consultation and customization to installation and post-sales assistance, ensuring a seamless collaboration.

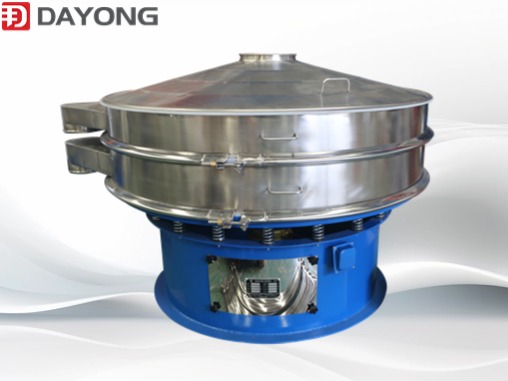

Conclusion:

Enhance your tire rubber particle processing with our customized rotary vibrating screens. Designed specifically for material classification, our machines offer efficient separation, reliability, and versatility. With our expertise and commitment to excellence, we are your trusted partner in optimizing tire rubber particle production efficiency and quality. Contact us today to discuss your requirements and embark on a successful cooperation that will transform your tire rubber particle processing capabilities.