Application of rotary vibrating screen in calcium carbonate slurry screening

Calcium carbonate slurry is a commonly used industrial raw material and is widely used in various fields. In order to improve the quality and purity of calcium carbonate slurry, screening is a key process step. This article introduces the application of rotary vibrating screens in calcium carbonate slurry screening and discusses its advantages in improving product quality and production efficiency.

Summary:

Calcium carbonate slurry is a commonly used industrial raw material and is widely used in various fields. In order to improve the quality and purity of calcium carbonate slurry, screening is a key process step. This article introduces the application of rotary vibrating screens in calcium carbonate slurry screening and discusses its advantages in improving product quality and production efficiency.

introduction:

Calcium carbonate slurry is widely used in papermaking, coatings, plastics and other industries. However, since its production process may produce particulate impurities, these impurities can reduce the quality and performance of calcium carbonate slurry. Therefore, screening is an important process step that can effectively remove particulate impurities and improve product purity and consistency.

Application of rotary vibrating screen in calcium carbonate slurry screening:

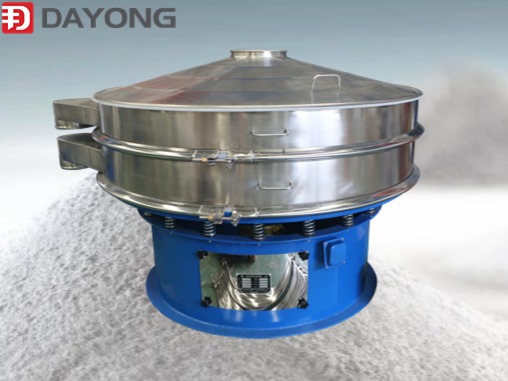

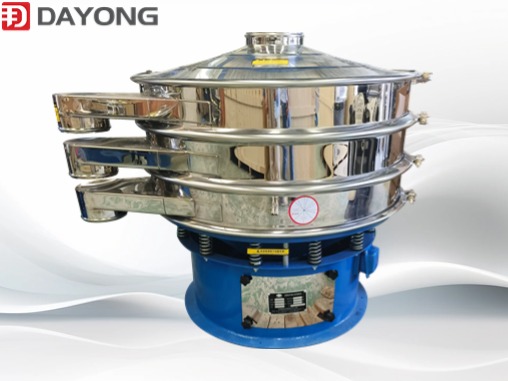

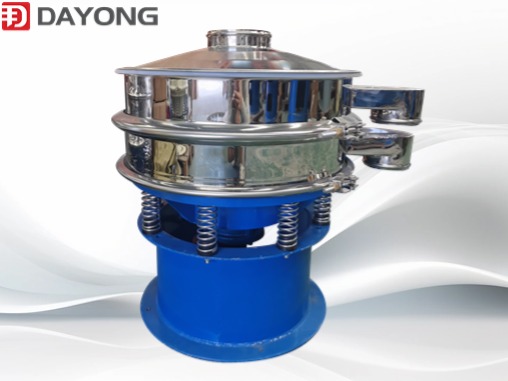

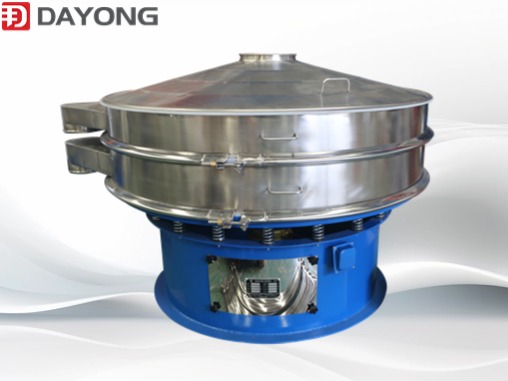

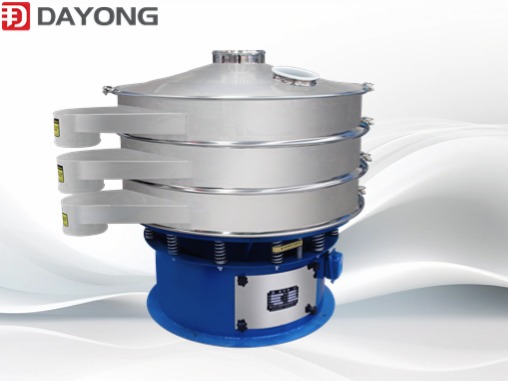

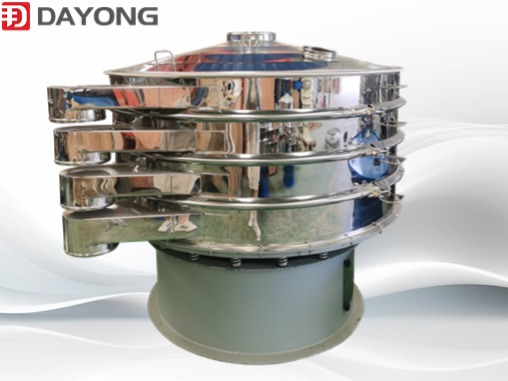

The rotary vibrating screen is a commonly used screening equipment, especially suitable for the screening process of liquid materials. In calcium carbonate slurry screening, the rotary vibrating screen can play the following roles:

Impurity removal: The rotary vibrating screen effectively separates particulate impurities, fibers and other solid impurities in the calcium carbonate slurry through vibration and screen mesh. This improves product purity and quality.

Particle size control: By selecting the appropriate screen size, the rotary vibrating screen can achieve particle size control of the particles in the calcium carbonate slurry. Different application fields have different requirements for particle size, and the rotary vibrating screen can be adjusted as needed to meet different particle size requirements.

Improved production efficiency: The rotary vibrating screen has efficient screening capacity and a large screening area, and can quickly process large amounts of calcium carbonate slurry. This helps increase production efficiency and capacity, reducing production time and costs.

Advantages and benefits:

Using a rotary vibrating screen for calcium carbonate slurry screening brings the following advantages and benefits:

Improve product quality: By removing particle impurities and controlling particle size, the rotary vibrating screen can significantly improve the quality and purity of calcium carbonate slurry, making the product meet high standards.

Increase production efficiency: The high-efficiency screening capacity and large processing capacity of the rotary vibrating screen can improve production efficiency and reduce screening time and labor costs.

Optimize the process flow: As a key process equipment, the rotary vibrating screen can help optimize the production process of calcium carbonate slurry and improve the overall efficiency and stability of the production line.

in conclusion:

Rotary vibrating screen has important application value in screening calcium carbonate slurry. By removing particulate impurities, controlling particle size and improving production efficiency, rotary vibrating screens can help improve product quality and reduce production costs. We encourage the use of rotary vibrating screens as screening equipment in the production of calcium carbonate slurry to optimize the process and obtain better production results.