100 Mesh Filter Separator Ing Machine Price Vibrating Sieve Screen

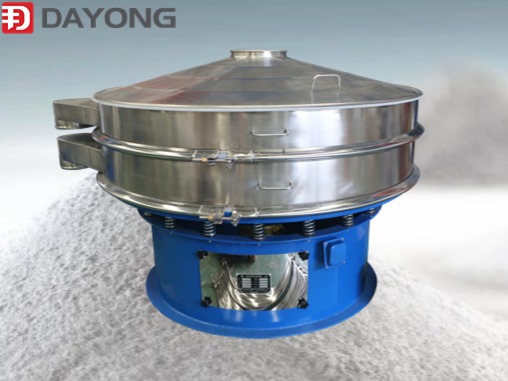

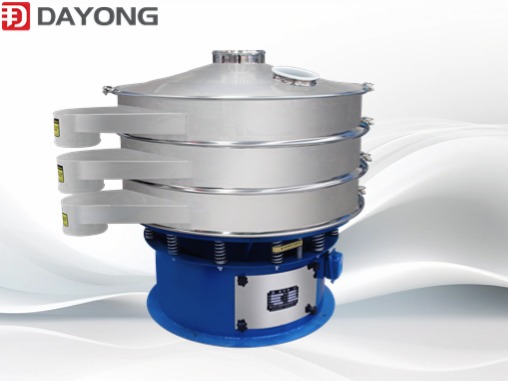

The rotary vibrating screen is composed of upper and lower parts, which are connected by steel springs. The upper part is composed of screen frame, round platform and vertical vibration motor, which is the working part of the equipment; The lower part plays a load-bearing role in the equipment. The rotary vibrating screen is made of vertical vibrating motor

Is the source of vibration. The exciting force can make the materials evenly distributed to each side from the central feeding port, so as to achieve higher screening efficiency. At the same time, it can also be used for screening of powder materials such as foundry sand, powder metallurgy and metal powder.

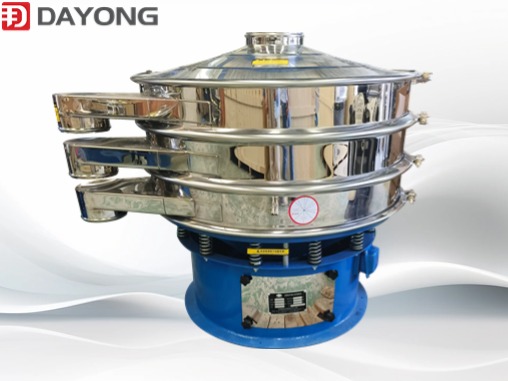

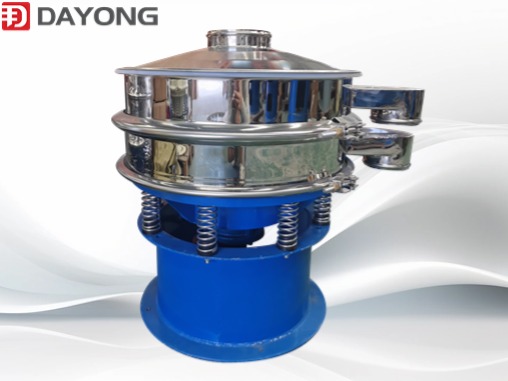

In order to improve the screening effect of rotary vibrating screen when screening fine materials, equipment such as ultrasonic system can be added. Change the phase angle of the hammer at the top and bottom of the vertical vibration motor, so as to change the movement direction of the raw materials in the food industry and achieve the goal of screening. At the top and bottom of the vertical motor, there is an eccentric hammer, which is considered as a vibration source. The eccentric hammer can convert the rotary motion of the motor into horizontal, vertical and inclined three-dimensional motion, and then transfer the motion to the screen surface.

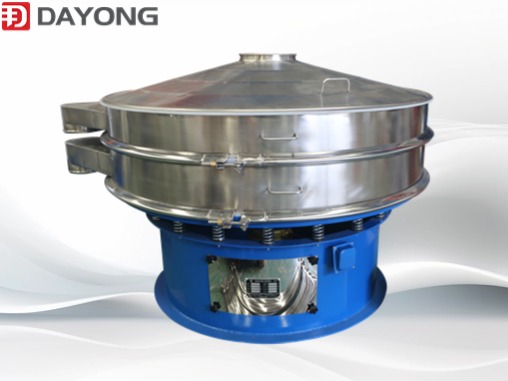

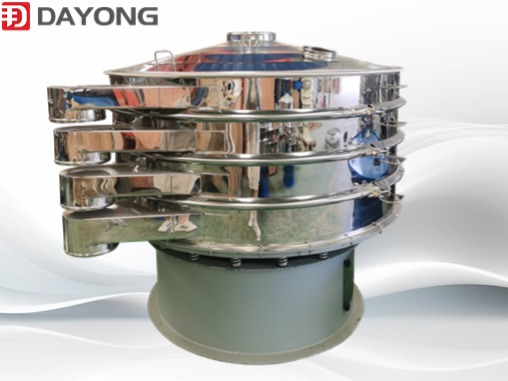

The round vibration screen is an inertial vibration screen of a single -axis circular weekly movement. The work of the round vibration screen depends on the inertia generated by the inertia motor and the eccentric board. Due to the vibration of the sieve box, the material is thrown out, so that a certain size of the material is sieved through the screen. Realize the screening goal. Because the magnetic motorizer is installed on the center of gravity of the sieve box, the two ellipse long shaft forms a Chinese character shape. The upper part of the elliptical long shaft of the import end is consistent with the exit direction, which is conducive to the diffusion of the material in the sieve box.